08045800054

- Home Page

- Company Profile

-

Our Products

- Centralised Single Shot Oil Lubrication System

- Twenty Four VDC Battery Operated Grease Lubricator

- Rotary Pump And Motor Pump Assembly

- Progressive Distributor Block

- Multiline Lubrication System

- Dual Line System

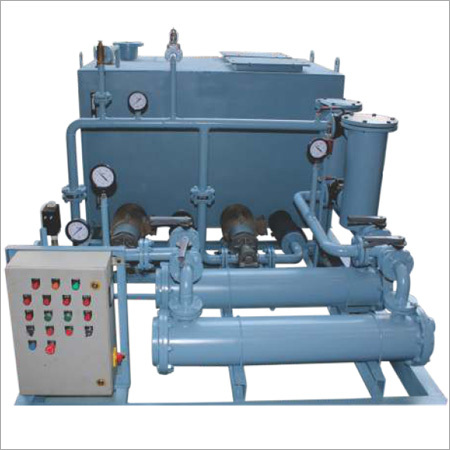

- Oil Circulation System

- Lube Van-Mobile Service Van

- Lube Workshop - Fluid Control System

- Mino Automatic Greasing System For Vehicles

- Barrel Grease/Oil Transfer Pump Assembly

- Air Oil Mix Lubrication System

- Grease Pump

- Extra Links

- Contact Us

Most Popular Products

|

Mino Automatic Greasing System For VehiclesMino Automatic Greasing Systems For Vehicles are apt for transmitting the grease as well as other highly viscous fluids. These machines can deliver work even under high pressure. They are suited to a wide variety of industries and regulate the process of grease transmission. These systems provide consistent lubrication and offer protection to the bearing as well as bearings seals. Mino Automatic Greasing Systems For Vehicles with their greasing capacity can perform extremely well and bring several benefits to the equipment operators. They are functional as the safer methods of supplying the exact amount of lubrication to bearings, lubrication points and bushings.

|

|

|

×

Add a mobile number to receive call from "CENLUB SYSTEMS"

×

Enter OTP

×

Share additional details for a quick response

×

Thank You!

Thank You for your valuable time. We have received your details and will get back to you shortly.

×

Get a price quote for Mino Injector System

×

Contact Details

CENLUB SYSTEMS

ISO 14001:2004 / ISO 9001 : 2008

ISO 14001:2004 / ISO 9001 : 2008

42, DLF Industrial Estate-1, Faridabad - 121003, Haryana, India

Phone :08045800054

Marketing Department

Mobile No. : 08800511336

Mobile No. : 08800511336

|

CENLUB SYSTEMS

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

✕

Contact Us

OTP Verification

Verification Code

Did not receive yet?

Resend OTP

Thank you!

We have received your requirements

For an immediate response, please call this

number 08045800054

✕

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

Confirm Your Requirement

Verification Code

Did not receive yet?

Resend OTP

Youre Done!

We have received your requirements and will reply shortly with the best price.

Products You May Like